[ad_1]

Over the previous few years, the tech business has been feeling the influence of unprecedented disruptions alongside the semiconductor provide chain. This provide chain—which spans from analysis and improvement to manufacturing, to the top use of the tiny chips that allow units from vehicles to cell telephones—has traditionally been unstable, simply swinging from surpluses to shortages on account of geopolitical and international financial elements. But, whereas the business’s cyclicality might by no means change, a safer and dependable system to safeguard and diversify the worldwide provide chain is feasible.

Addressing semiconductor provide chain dangers

Even earlier than the latest provide chain challenges, political leaders world wide have been taking a detailed take a look at the present semiconductor provide chain mannequin. Semiconductors throughout the worldwide financial system have the potential to form provide chains for quite a few business electronics, in addition to elements important to crucial infrastructures, akin to telecommunications and monetary providers. Maybe extra importantly, the provision of semiconductors has worldwide safety implications, affecting nationwide and regional protection and emergency response capabilities. Given its geopolitical influence, many policymakers concluded that the prevailing semiconductor provide chain mannequin is just too dangerous and are responding accordingly.

A few of that danger is being addressed at nationwide and regional ranges, such because the U.S. CHIPS Act and the EU Chips Act. Nevertheless, investments in these initiatives are closely centered on constructing new wafer fabrication amenities, or “fabs.” Whereas fabs make up a crucial a part of the manufacturing course of, elevated fab manufacturing alone can’t higher safe the worldwide provide chain.

Broadcom

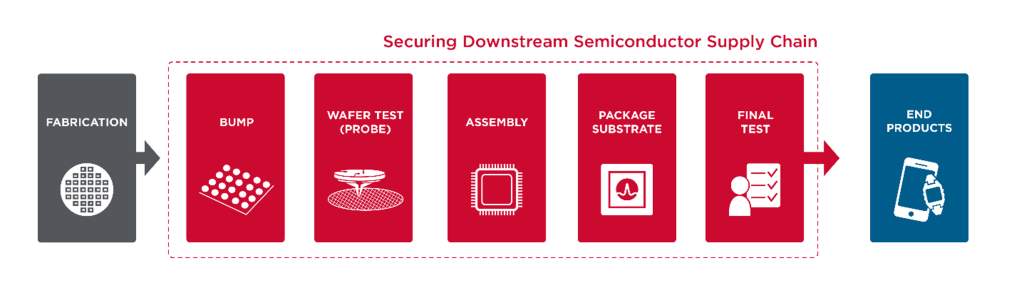

There may be a lot much less consciousness of what occurs after chips depart the fab. These post-fab processes—what the business calls “downstream” or “back-end” operations—comprise a crucial a part of the chip-making provide chain they usually, too, stay extremely susceptible.

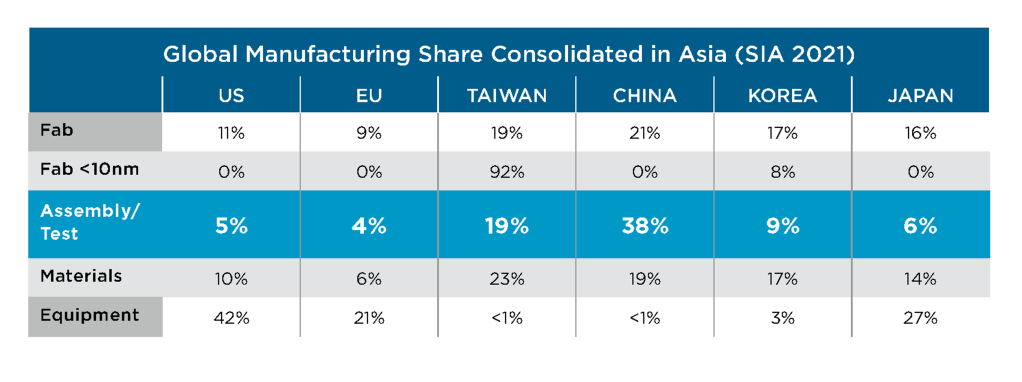

A 2021 report by the Semiconductor Business Affiliation (SIA) highlights that the overwhelming majority, practically 80%, of the world’s semiconductor wafer fab manufacturing is finished throughout simply 4 international locations in Asia, whereas lower than 10% is finished in Europe. And with regards to manufacturing the world’s most technologically superior chips, none of it happens in Europe or the U.S.

Supply: SIA 2021 State of the Business report

Wafer fabrication is probably the most well-known piece of the semiconductor manufacturing provide chain, however there are different mandatory steps that happen after chips depart the fab and earlier than they find yourself in a sensible telephone or vehicle. Practically all post-fab steps are likewise concentrated in those self same 4 international locations in Asia. The truth is, Asia is house to greater than 90% of the post-fab, downstream provide chain, with solely 4% in Europe.

Making a European-based mostly post-fab ecosystem

A specialised, geographically dense downstream provide chain faces quite a few dangers, starting from pure disasters to regional or international geopolitical disruptions. To completely safeguard the semiconductor provide chain, fabrication in addition to the post-fab processes should be diversified.

There isn’t any magic answer to this problem. The near-term capital and operational expenditures to construct downstream processes within the U.S. and Europe are substantial, albeit they’re nowhere close to as massive as what’s required for constructing a brand new fab.

However these prices are usually not insurmountable. Public funding would assist meet the upfront prices of constructing and working downstream infrastructure ecosystems. The EU and its member-states may encourage funding in fabs andthe crucial elements of the post-fab provide chain that comply with.

With out that dedication from the general public sector, non-public firms might not be keen or able to overcoming these challenges on their very own. Extra importantly, the chance to advance an more and more safe international provide chain could possibly be misplaced with out it.

Diversifying the present provide chain

Provide chain diversification isn’t solely in Europe’s safety pursuits, however it is usually within the broader pursuits of nations globally—together with the U.S., which acknowledges the necessity to take away danger from the present provide chain. The truth is, a safer and diversified provide chain was singled out as a shared objective of the U.S.-EU Commerce and Know-how Council. Nevertheless, this needs to be extra of a worldwide effort throughout Europe, the Americas, and Asia as a way to eradicate vulnerabilities in your entire provide chain.

As a world firm that stands to profit from a safer provide chain, Broadcom, a world semiconductor and infrastructure software program supplier, would welcome alternatives to enhance its downstream manufacturing variety. Safeguarding the provision chain, together with the post-fab processes, can cut back the probability of disruption from a bunch of potential occasions for not solely business industries, but in addition governments investing in crucial applied sciences that vary from superior telecommunications to cloud infrastructures.

So, as European and American governments take into account their very own investments, they need to not lose sight of the massive image. Constructing fab capability isn’t the one answer to the provision chain danger puzzle. Trying past the fab and securing downstream processes may have important, optimistic impacts on international stability and the safety of the provision chain worldwide.

For extra details about Broadcom’s semiconductor improvements, go to broadcom.com/weblog.

About Hock Tan:

Broadcom Software program

Hock Tan is Broadcom President, Chief Govt Officer and Director. He has held this place since March 2006. From September 2005 to January 2008, he served as chairman of the board of Built-in System Know-how. Previous to turning into chairman of IDT, Mr. Tan was the President and Chief Govt Officer of Built-in Circuit Methods from June 1999 to September 2005. Previous to ICS, Mr. Tan was Vice President of Finance with Commodore Worldwide from 1992 to 1994, and beforehand held senior administration positions with PepsiCo and Basic Motors. Mr. Tan served as managing director of Pacven Funding, a enterprise capital fund in Singapore from 1988 to 1992, and served as managing director for Hume Industries in Malaysia from 1983 to 1988.

[ad_2]