[ad_1]

How ought to fashionable manufacturing appear to be? All of us have seen motion pictures or learn books concerning the future the place robots and machines run the whole lot, together with factories and vegetation. So, the query is: how quickly will this fiction change into actuality, and can it ever be absolutely?

It is perhaps a bit presumptuous to imagine that we’re already dwelling within the futuristic period the place the trade is self-conscious and doesn’t want any human involvement in anyway. Nonetheless, these days, manufacturing is altering quickly and turning into “Business 4.0”.

There are quite a few applied sciences the utilization of which turns manufacturing for the higher, however one of many primary drivers that stands out and pushes it considerably additional is the Industrial Web of Issues.

The Industrial Web of Issues, or IIoT, is a subdomain of the Web of Issues. On this case, linked “issues” that underpin the entire idea of IoT are applied into the manufacturing course of.

Frequent IoT units, like wearables or good audio system, are designed to ease the on a regular basis routine and produce new experiences to the client. IIoT, however, pursues one other purpose, which is to optimize manufacturing, useful resource utilization, and high quality of products.

IIoT consists of linked units that monitor and acquire knowledge on the exercise and state of apparatus, and software program that processes the info. Such connectivity created situations for the subsequent industrial revolution and led to the looks of the time period: “Business 4.0”. This stage of producing implies the automation of conventional industrial practices, machine-to-machine communication, prognosis, and troubleshooting finished by machines with out human involvement.

Get to know extra concerning the fascinating subject – software of information mining in IoT and its position within the manufacturing trade in our weblog article:

IIoT is relevant to many manufacturing sectors, for instance, IoT automotive, electronics, aerospace, heavy industrials, oil, and gasoline. The worth, significance, and affect of IIoT are hardly exaggerated, contemplating that it’s a answer for:

- inadequate productiveness;

- excessive fee of human errors that have an effect on the standard or pace of manufacturing;

- breached safe measures;

- complicated and resource-demanding upkeep of the tools.

On this article, we are going to describe the sensible elements of IIoT growth and implementation in your corporation and why each producer wants linked units to remain aggressive out there. So, let’s dive into the world of IIoT!

The IIoT market

IIoT is a fast-growing sector with more-than-decent prospects. As of 2021, the dimensions of the market is estimated at USD 76.7 billion and anticipated to balloon to USD 106.1 billion by 2026 in keeping with some. That makes for a 6.7 % CAGR (compound annual progress fee).

One other, extra optimistic report compiled by Grand View Analysis, Inc. predicts that the IIoT market will attain a whopping USD 1.11 trillion by 2028, implying a CAGR of twenty-two.8%, which is a more-than-impressive progress fee regardless of inflation issues.

The highest three markets for IIoT are the Asia-Pacific area, North America, significantly the US, and Europe, with Germany within the lead trailblazer position on the continent. It’s anticipated that Chinese language, American, and Western European funding into IoT down the highway can be rising at a CAGR of 13.4%, 9.0%, and 11.4% respectively.

A number of the most well-known IoT {hardware} corporations are Bosch, Cisco, Dell, Intel, and Lenovo.

COVID has slowed down the enlargement of this market, however it’s anticipated to proceed its ascent larger by way of affect on international enterprise. Based on Vodafone analysis, 84% of companies that applied IoT mentioned that it had proven optimistic results and even helped to beat some challenges caused by the pandemic. We will conclude that IoT applied sciences reconfirmed and proved as soon as once more their relevance for contemporary companies. Resulting in it being ever extra in demand and offering an incentive and push for tech capabilities to be always enhancing and progressing.

Want a crew for IoT software growth?

We provide growth with good high quality/price charges.

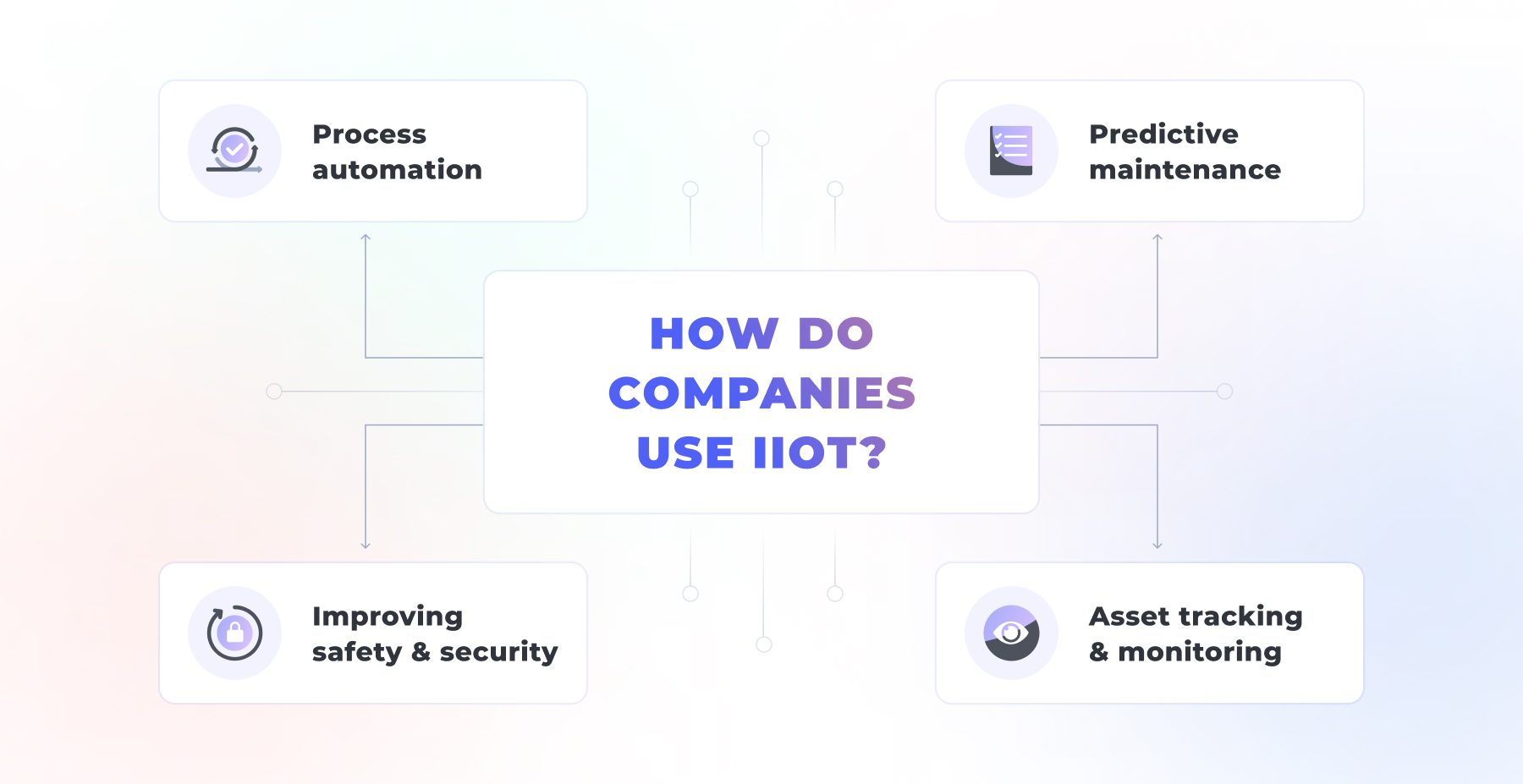

Industrial IoT Use Circumstances

IoT units join the completely different elements of producing, permitting simple knowledge alternate between machines, platforms, and folks. Fixed connectivity opens the gate for numerous enhancements within the movement of producing processes. Listed below are a few of them.

Course of automation

IoT purposes enable one to robotically collect enormous quantities of information. This course of beforehand absolutely relied on guide labor, which undoubtedly took extra time, and thus cash. Furthermore, good sensors which can be applied within the tools present larger accuracy and take away the probability of errors generally made by people.

IoT permits good factories, and normally, it really works the next manner: sensors acquire knowledge and monitor machine utilization and manufacturing. In case of errors or when human involvement is required, the system provides an alarm or robotically adjusts the tools. Listed below are some examples of how it’s utilized in completely different industries:

- within the power sector, particularly with renewable power sources, sturdy winds can hurt the photo voltaic tools; IIoT options can monitor when the wind is damaging photo voltaic panels and ship instructions to readjust them to attenuate the affect;

- in manufacturing, IoT can analyze the utilization of power and optimize it; Airbus, one of many leaders within the aerospace trade, states that on this manner power consumption could possibly be decreased by 20 %;

- once more in manufacturing, it’s doable to optimize the availability chain: car producer Magna Steyr established a system, which tracks the variety of belongings required for environment friendly work and robotically sends orders for replenishment.

Predictive upkeep

Gear is a giant a part of each manufacturing course of; there are varieties of manufacturing however the widespread theme is that all of them require upkeep.

IoT-sensor can monitor the state of the tools, discover the indicators of degradation and alert the employees beforehand when the restore is required. As a substitute of getting sudden breakdowns, you will get related knowledge, run a predictive evaluation and plan your upkeep schedule forward of time, allocate assets fairly and maintain the manufacturing going.

Predictive upkeep gives:

- discount in upkeep price, as the businesses don’t have to resort to disaster administration and really have an opportunity to plan and optimize the upkeep;

- enhanced safety, because the tools is underneath fixed monitoring and the probability of accidents throughout work decreases.

Asset monitoring and monitoring

Asset monitoring is a apply that may enhance enterprise efficiency, however folks actually don’t pay practically sufficient consideration to it.

The reason being that it’s a resourceful activity. Nonetheless, with IoT monitoring, it turned an entire lot simpler. The corporate simply wants to put sensors on their tools, instruments, uncooked supplies, and ultimate merchandise. Asset monitoring helps monitor issues intently, which is particularly helpful for issues like maritime transport of products. With the info simply accessible, corporations could forestall doable damages throughout supply, and transport crews can alter local weather management of temperature-sensitive items being shipped.

Enhancing security and safety

Other than maintaining tabs on tools and its state, IoT can enhance different elements of producing security. Related good tools could produce knowledge for atmosphere evaluation that may assist pinpoint areas of weak point. Every time there’s a hazard looming, the system will alert facility managers.

Some particular use instances could also be:

- distant entry to tools that may be harmful with bodily proximity;

- environmental sensors that may notify staff that they’re approaching unsafe areas;

- built-in security techniques with emergency response buttons obtainable for employees to sound the alarm.

?

Associated article

Industrial IoT examples

A number of industrial giants already embraced IIoT of their apply and got here out happy with the outcomes. Let’s look intently at their expertise.

Caterpillar

Caterpillar, a US Fortune 100 firm that manufactures heavy equipment, utilized IIoT to its enterprise within the ‘90s. It’s one of the vital profitable examples of implementation of Industrial IoT within the USA. The corporate has greater than 500,000 linked belongings all around the world and the largest linked fleet within the trade.

Caterpillar, a US Fortune 100 firm that manufactures heavy equipment, utilized IIoT to its enterprise within the ‘90s. It’s one of the vital profitable examples of implementation of Industrial IoT within the USA. The corporate has greater than 500,000 linked belongings all around the world and the largest linked fleet within the trade.

IIoT is applied there for predictive upkeep of the machines and fleet monitoring and administration. However the firm didn’t cease there, and is now producing merchandise for purchasers which have built-in, built-in IIoT expertise capabilities; — for instance, their excavators are significantly simpler to function than are conventional ones.

Furthermore, Caterpillar’s utilization of IoT positively impacts purchasers in that the tools and equipment have superior utilization: for instance, via predictive upkeep, the corporate managed to save lots of over 600 thousand USD for a mining shopper of theirs, whereas one other shopper from the trade acknowledged that utilizing Caterpillar’s autonomous automobiles elevated their productiveness by 20%.

Shell

As you could very properly know, Shell is a British-Dutch firm that is without doubt one of the greatest oil and gasoline corporations on the earth. They applied IoT sensors in a particular venture in Nigeria and managed to save lots of over 1 million USD via shut monitoring of the oil fields. The system was in a position to observe the state of the pipeline, its temperature, and strain.

As you could very properly know, Shell is a British-Dutch firm that is without doubt one of the greatest oil and gasoline corporations on the earth. They applied IoT sensors in a particular venture in Nigeria and managed to save lots of over 1 million USD via shut monitoring of the oil fields. The system was in a position to observe the state of the pipeline, its temperature, and strain.

The challenges the corporate confronted throughout the implementation had been the issue of the floor the place the pipeline was located, the power to attach via lengthy distances, and scalability. The ultimate options, after all, dealt with these problems with grace.

Komatsu

The Japanese mining equipment producer, Komatsu, experiences the spectacular enchancment of IIoT implementation. The corporate has its personal IoT system referred to as KOM-MICS that gathers knowledge from sensors put in on machine instruments and robots. Because of a continuing movement of information, the corporate managed to extend the machine operation fee (the period of time a machine runs correctly at a time) by 25 %.

The Japanese mining equipment producer, Komatsu, experiences the spectacular enchancment of IIoT implementation. The corporate has its personal IoT system referred to as KOM-MICS that gathers knowledge from sensors put in on machine instruments and robots. Because of a continuing movement of information, the corporate managed to extend the machine operation fee (the period of time a machine runs correctly at a time) by 25 %.

Later, with the rise of cloud computing, the corporate selected Azure by Microsoft to retailer the info from machines, which allowed simpler scaling up and including extra machines from worldwide branches to KOM-MICS.

Plan to enhance the efficiency of your manufacturing?

Develop software program to use the info from IoT sensors!

Industrial IoT corporations

An environment friendly IIoT ecosystem consists of various components: {hardware}, networks, connectivity, platforms, and purposes. We collected some high market gamers in talked about niches to offer you a picture of the sphere.

{Hardware} is manifested in bodily type via modules, sensors, and gateways. Modern means in {hardware} widens the probabilities for the entire IoT ecosystem. One of many high corporations right here is Bosch, a German producer that produces several types of sensors (dimension, displacement, and vibration sensors), video techniques, and robots.

Connectivity is one other essential a part of IoT. It gives a wi-fi connection between units. Corporations normally use low-power large space networks, or LPWAN, as it’s the best suited radio band for IoT. Right here the primary gamers are telecommunications corporations like Verizon, Vodafone, and AT&T. The latter made a deal with IIoT platform Howden Uptime to offer international connectivity for higher safe cloud options.

Different large corporations with involvement which can be value mentioning are Microsoft, IBM, Cisco, and Intel. Together with Bosch which we already talked about, these corporations provide a variety of services and products, from networks (mobile, Wi-Fi, Ethernet) to cybersecurity options.

Advantages of IIoT

IIoT has a variety of doable purposes, plenty of which have already confirmed their value via optimistic affect on companies. The principle however not the one benefit is improved total effectiveness and efficiency.

Elevated effectivity

It’s the options that deliver an actual change: with a number of processes automated, manufacturing turns into faster however merchandise nonetheless retain a excessive stage of high quality. When IoT is used to observe machine utilization, it will increase productiveness by 10 to 25%. Information collected by IoT units also can deliver as much as 20% larger product depend from the identical product line.

New enterprise alternatives

Entry to knowledge on the manufacturing course of could deliver an entire new standpoint on how the corporate ought to work. IoT sensors and appropriate algorithms can analyze the efficiency of your tools and machines, electrical energy and water utilization, provide chain effectivity, and so forth. New perception can present you methods to chop spending or discover new income streams.

Elevated items high quality

IoT sensors enable detecting injury and defects on the meeting line. This fashion, it’s simpler to handle the issue earlier than the product goes to the market. Automation additionally decreases human involvement, therefore the probability of errors decreases too.

Optimized prices

Contemplating the aforesaid, IIoT considerably modifications and shapes how fashionable factories evolve. The choices change into predictive as a substitute of reactive, the variety of chaotic actions decreases, and the strategy switches to being wholly data-driven. All of this results in extra affordable spending and price range allocation.

ROI of IIoT

IIoT can deliver many advantages, however what concerning the precise monetary affect of the Industrial Web of Issues on the enterprise? With out particular numbers, the entire implementation can be in useless and finished just for the sake of expertise.

To show the profitability of the funding in IIoT, we advise you employ the ROI calculator and get knowledge you could function. Nonetheless, to generate a related index, you want a transparent understanding of how IIoT can be utilized and the way it will have an effect on the next elements:

- tools upkeep and quantity of downtime hours;

- what enterprise processes can be automated and streamlined;

- what indicators (prices, time-to-market, and so forth.) will change and the way;

- how labor compensation will change.

So, right here is a vital conclusion: IIoT implementation isn’t solely a one-time venture that issues technical implementation. It needs to be approached as a world change in enterprise processes and begin with an issue. That you must ask all stakeholders: what drawback can we need to remedy with IIoT?

Ranging from this level, you may be sure to create a method and analysis each step. This can result in deliberate selections and exact objectives. Finally, your IIoT implementation may have actual worth that may be measured in ROI and hundreds of {dollars} saved.

Fundamental Dangers Related to IIoT

The Industrial Web of Issues is the longer term, but it surely nonetheless creates new challenges for corporations even with all optimistic sides. Listed below are some main of them.

IIoT calls for notable investments

Adopting IIoT requires enormous bills: {hardware}, software program, offering connectivity, upkeep, and so forth. The market presents options in numerous worth ranges, however both manner, the funding nonetheless can be fairly vital.

However clear objectives and technique can mitigate this concern, particularly if you want to justify the IIoT adoption to board members or C-level executives. With the correct implementation strategy, IIoT will repay and have an honest ROI, and this can be your ultimate decisive argument.

Fixed connectivity

IIoT requires a powerful connection. Connectivity outages are a giant situation for good factories, which can result in extreme penalties. Firstly, it could trigger downtime of units and block manufacturing which ends up in monetary losses. Secondly, it additionally could trigger security issues, particularly if the manufacturing facility makes use of IIoT sensors to regulate harmful tools or monitor hazardous zones.

The problem right here is discovering a dependable vendor that may fulfill all your necessities, guarantee connectivity of each required location and supply minimal downtime.

Compatibility of legacy and IIoT infrastructure

IT/OT convergence is a good problem for producers. OT is normally sluggish to adapt, so they’re already outdated and never absolutely suitable with new applied sciences like IIoT. On the similar time, factories received’t substitute legacy techniques as a consequence of monetary causes solely.

So, the purpose of IT specialists and distributors right here is to create migration methods that received’t interrupt manufacturing and make sure the integration of all techniques.

IoT ability hole

Although IoT is a fast-growing area, there may be nonetheless a scarcity of competent specialists. This hole in information could create some challenges for you, particularly if it’s the primary encounter with IoT to your in-house IT crew.

Therefore, discovering a dependable IT vendor is essential for profitable IoT implementation. Contemplate involving exterior assets to cowl the necessity for this particular experience.

Security and safety issues with IIoT

Regardless of all of the positives, IIoT has an enormous weak point, which is susceptibility to cyberattacks. Industrial IoT units aren’t normally created with cybersecurity being a precedence, however any producer ought to assure safety from the specter of outdoors interference.

The extra accountability IoT units acquire, the extra injury to the manufacturing facility could also be finished in such an occasion. If manufacturing is robotically managed and relies upon completely on knowledge from the IoT sensor, hackers’ interference could spoil your merchandise or wreck the tools. Compromised units may not give correct and dependable information on the state of apparatus, which can result in machines unknowingly going out of order and turning into inoperable and finally resulting in accidents that might have been averted with the correct security and safety measures.

The doable threats are:

- gadget hijacking, when malware takes over the management of the gadget and hides the actual fact of a takeover;

- knowledge siphoning, when the hacker can get entry to the info transferred via Industrial IoT units;

- knowledge breaches, when the attacker reaches the central community with delicate knowledge;

- gadget spoofing, when the attacker interferes between the IoT gadget and networks or cloud and sends the compromised knowledge, whereas the system identifies them as a functioning gadget;

- denial of service assault, when the hacker spams the units with a lot visitors that they will’t perform accurately.

To keep away from cyberattacks and make sure the safety of IIoT environments, producers ought to:

- set up common IIoT upkeep;

- implement the chance evaluation modules;

- comply with encryption requirements;

- monitor and log each occasion finished by the units.

IIoT licenses, protocols, and requirements are additionally an essential a part of safety and security. There are two primary varieties of protocols: IoT knowledge protocols (MQTT, CoAP, AMQP, DDS, HTTP, WeebSocket) and community protocols (Wi-Fi, Bluetooth, ZigBee, Z-Wave, LoRaWan). IEEE Requirements Affiliation additionally created a record of required protocols for IoT.

Need to save this data? Obtain our PDF report on IIoT.

IIoT and Integration with Different Applied sciences

The potential of IIoT is nice, but it surely generates huge worth whereas being built-in with different applied sciences and items of software program. Utilizing such a mix, the corporate will get a chance to achieve the next stage of automation.

Enterprise Useful resource Planning System

ERPs have all rights to be named legacy techniques, nevertheless, they’re nonetheless in demand by producers. ERP software program connects the entire firm, and collects beneficial knowledge however nonetheless has its personal drawbacks (particularly old-school, on-premise techniques).

Nonetheless, IIoT can cowl these gaps and enhance ERP efficiency. For instance, it impacts grasp knowledge considerably. This data consists of manufacturing orders, materials varieties, good points and receipts, planning necessities. Beforehand, this knowledge was as soon as saved within the system and that’s all. Now, IIoT permits fixed synchronization, and therefore, a sensible illustration of operations.

Furthermore, IIoT will give higher visibility and monitoring for each a part of merchandise. This can positively have an effect on the availability chain, transport, product recollects, and even buyer providers.

Integrating your ERP with IIoT is an efficient event to maneuver the system to the cloud. Cloud ERP options demand much less upkeep, they are often accessed remotely, they usually grant you extra agility which is certainly a vital function proper now.

Associated Article

Synthetic Intelligence

AI is one other development within the subject of good manufacturing, and it’s no surprise! Synthetic intelligence and machine studying algorithms use the info that’s generated by IIoT sensors to self-manage operation processes.

The largest profit right here is the truth that human involvement isn’t vital right here. AI proceeds, analyses, implements knowledge, and makes operational selections. For the large factories the place the amount of information is simply too large for guide processing, AI relieves a large amount of strain and human effort.

In search of a vendor who can offer you a {custom} IIoT answer?

We will develop {custom} IIoT software program, combine it together with your ERP or AI answer.

High IoT Conferences 2022

Need to be taught the most effective use instances and examples of profitable IIoT growth and implementation? We gathered high occasions that may occur subsequent 12 months with high audio system from Microsoft, Samsung, Bosch, and main analysis institutes.

- Industrial IoT Convention, February 8-11, 2022, Fort Lauderdale, FL, US

- Embedded IoT World, April 28-29, 2022, TBA

- IoT Options World Congress, Might 10-12, 2022, Barcelona, Spain

- The World AI IoT Congress 2022, June, 6-8, 2022, Seattle, US

- IoT Week, June 20-23, 2022, Dublin, Eire

Why select GBKSOFT for IIoT growth

Software program is a vital a part of any IIoT system that powers units and makes the connection practical and helpful. GBKSOFT presents IoT growth for producers in numerous industries.

We provide:

- IoT and IIoT software program growth and testing on actual units;

- IoT integration with AI and ML;

- manufacturing ERP growth from scratch and ERP integration with IIoT;

- upgrading of your legacy manufacturing options.

As a software program growth firm, we offer you:

In conclusion

Manufacturing is quickly altering, embracing new and progressive applied sciences. Handbook, routine labor can’t compete with automated machines — standardized, good manufacturing not solely will increase productiveness but additionally ensures product high quality, improves worker security, and optimizes prices.

The Industrial Web of Issues is without doubt one of the primary applied sciences that make Business 4.0 doable. With the fixed capability to observe any course of, it modifications the paradigm of the manufacturing operation, making the predictive strategy the brand new customary.

IIoT is the way forward for any manufacturing facility. The producers who search for the best way to enhance their efficiency ought to contemplate the implementation of IoT applied sciences, because it’s already confirmed to be an environment friendly manner during which world-leading organizations innovate and modernize to proceed being cutting-edge.

In search of a crew for IIoT growth?

We’re able to offer you software program for environment friendly knowledge software!

[ad_2]